|

Collect-Aire's

1/48 scale

YF-23 “Black Widow II”

by

"Bondo" Phil Brandt

|

|

|

Northrop-McDonnell YF-23

“Black Widow II” |

HyperScale is proudly supported by

Squadron.com

We Interrupt Regular Programming...

Bondo Industries now interrupts HyperScale Broadcasting Network’s

mostly WWII, most-of-the-time programming to showcase an example of

what’s been happening in the ensuing six decades.

Our firmly WWII-ensconced brethren may be shocked to learn that, in the

21st Century, there are actually aircraft that don’t have props or

reciprocating engines, aircraft that regularly fly above Mach 2,

airplanes that fire their air-ro-air missiles while the enemy is beyond

visual range, and, what I’m sure will be most unsettling to Luftwaffe

enthusiasts, that the German Air Force flies many American-designed

airframes!

As representative of the legion of aerospace advances, we will examine

the construction of a 1/48 Northrop YF-23 “Black Widow II.”

Background

From all reports, the 1991 Next Generation Air Superiority Fighter

flyoff between the Lockheed-Martin YF-22 “Raptor” and the

Northrop-McDonnell YF-23 “Black Widow II” was an extremely close affair.

Although the YF-23 excelled in various flight aspects and was thought by

some to be aesthetically more pleasing, the reason that the nod went to

Lockheed’s innovative design might have been because of that company’s

lengthy record of successfully getting advanced products out the door,

whereas Northrop had in the past experienced design and production

difficulties.

The Build Begins

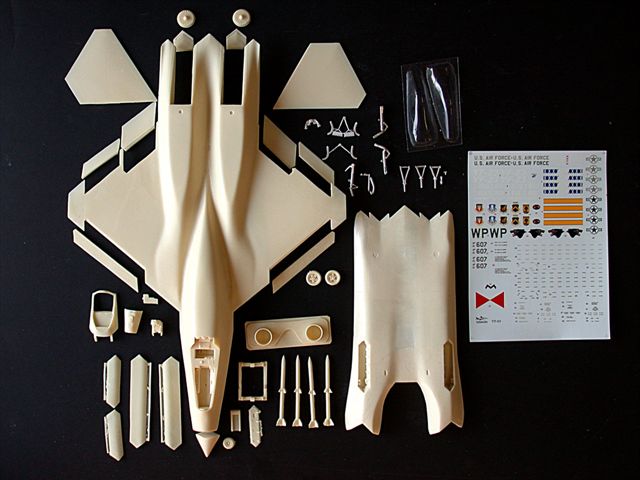

At first look, the Collect-Aire kit seemed to be (for a Collect-Aire

release, at least) a relative no-brainer.

The massive main airframe, including wings, was formed out of just

two large resin castings, the upper half integral with the wings and a

lower half including intake trunks. All the modeler had to do was add

the slabs and glue in the metal gear. Yeah, right...

Molding

Although overall molding was very smooth, with minimal warping

(exception: slats and ailerons which maintained an annoying “memory” to

regain warping) and very petite engraving, some of these qualities were

for naught because your correspondent’s kit had serious casting flaws in

the lower, aft fuselage portion, where some areas were literally paper

thin, and it was obvious that additional resin had been poured on top of

already cured resin in an attempt to effect a fix.

Then there were the odd surface discontinuities on the top surface of

both the large trapezoidal wings. That is, there was a large portion of

outer wing surface that was visibly thinner (by just a few thousandths)

than the rest of the wing. The discontinuity was very noticeable and ran

across each wing chord in a wavy line, requiring aggressive block

sanding and applications of 3M Blue Acryl lacquer putty. Some might say

it was just another day at the Difficult Kit Division of Bondo

Industries!

Fit

One might think that full length, cast-in intake trunks are a very

nice innovation in a resin jet kit. Mebbe so...if the inner trunk walls

align properly, with a minimal seam between top and bottom castings. If

you’re betting that this didn’t happen, you’d be a winner. Aligning the

monolithic top and bottom halves required hot water and large C-clamps

to coax the assembly together with epoxy glue. Getting the outer

surfaces to align–especially the zigzag fuselage trailing

surfaces–caused a significant, and I do mean significant, misalignment

of the intake trunk joints. Since said trunks are approximately four

inches long, it’s virtually impossible to sand any further back than,

say, two inches. Luckily, the intakes are under the wings and the trunks

have a lot of curvature, so one literally has to peer into the depths of

each trunk with a mini-light to see the gaps that exist. I even

fashioned a putty application tool in an ultimately vain attempt to fair

in the misaligned seams all the way back to the compressor faces.

The severely angled slabs were butt-joined one at a time to the

empennage with five-minute epoxy. I would hold the fuselage at such an

angle that the slab would be vertical, and I made small adjustments

until the epoxy cure was enough to hold things in alignment.

Landing Gear

Luckily the gear struts are cast metal, because this is a large,

heavy model.

I’ve even worried that the trailing axle, knee-action design of the

mains might not be able to stand up to the weight, but so far, so

good...

Cockpit

The cockpit is fairly plain, with a cast metal instrument panel and

an apparently cloned resin seat .

I chose a more detailed aftermarket seat.

Clear Parts

The vacuformed windscreen/canopies (two copies are provided) are

fairly clear and thin, but must be cut apart if you want an open cockpit

configuration. The “saw-blade” aft edge lines of the canopy are very

hard to discern in the vac molding, and much care had to be used in the

trimming.

To Collect-Aire’s credit, they provide a one-piece resin canopy interior

structure which saves a lot of scratchbuilding, again, if an open

configuration is desired. What isn’t included is a windscreen structural

arch, and this had to be fabricated from .080 sheet and the trusty

Dremel-with-sanding-drum.

Weapons

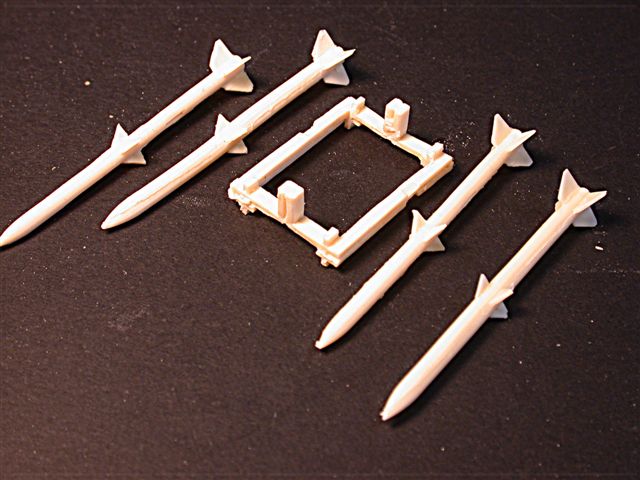

Collect-Aire provides four resin missiles (AMRAMS?) and a launch rack

which is embellished with cast metal bay door mechanisms and details. I

elected to pass on an opened weapons bay and extended launcher/missiles

because IMO the whole assembly adds a clunkiness to the overall sleek

appearance of the airframe.

Of course, by skipping the opened bay doors I was inviting the task

of gluing and puttying the ill-fitting doors.

Finishing

Multiple iterations of the old lacquer primer/Blue Acryl/wetsand/rescribe

routine eventually provided a decent surface for the three shades of

Testors Acrylic (gunship gray, dark ghost gray and light ghost gray)

which mimic the scheme used by many of today’s F-16s. There were some

small areas in which the resin seemed to “bleed through” the paint

layers (even though the resin had been scrubbed with soapy water and

rubbed down with lacquer thinner), creating small, weird shiny areas.

Fortunately the final dusting with Testors clear flat minimized this.

Markings

This modeler isn’t nuts about prototype schemes , preferring real

world operational ones. Thus, I took advantage of the kit’s 8th Fighter

Wing “Wolfpack” hypothetical markings that might’ve been used had the

YF-23 deployed to Kunsan, South Korea as an F-16 replacement. Hey, it

coulda happened! The excellent decals were custom-designed by Gerry

Asher of Fox Three Studios in Fort Worth. Unfortunately, locations for

some of the stenciling were not depicted in the instructions. Even the

prominent “Wolfpack” logo locations were not shown, so I copied the

location of the logo from Kunsan F-16 pix. Some additional stencils were

added from an Aeromaster F-16 sheet.

One more resin “beating”! But, as with most of Collect-Aire’s offerings,

this bird’s is (so far) the only 1/48th game in town.

We now return you to our regularly scheduled WWII programming.

Click on the thumbnails

below to view larger images:

[../../photogallery/photo00019609/real.htm]

Model, Images and

Text Copyright © 2007 by "Bondo" Phil Brandt

Page Created 31 July, 2007

Last Updated 24 December, 2007

Back to HyperScale

Main Page

|

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |