|

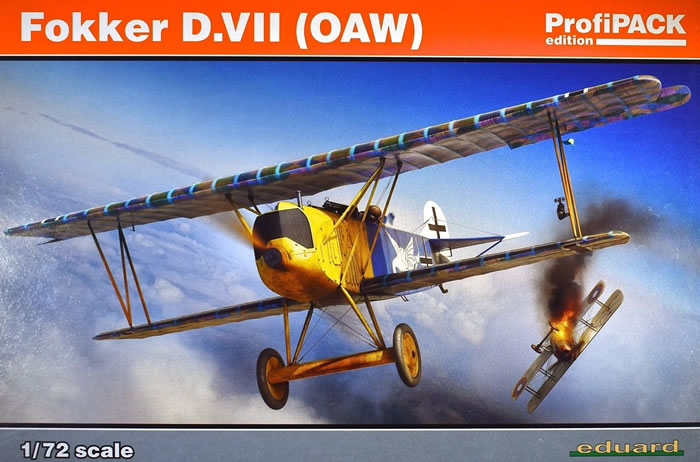

Fokker D.VII (OAW)

Eduard ProfiPACK, 1/72 scale

S

u m m a r y |

| Catalogue Number: |

Eduard Kit No. 70131 - Fokker D.VII (OAW) ProfiPACK |

| Scale: |

1/72 |

| Contents and Media: |

100 parts in grey coloured plastic; colour photo-etched fret; self-adhesive die-cut masking sheet; markings for five aircraft |

| Price: |

USD$39.96 plus shipping,

available online now from Eduard

GBP£32.30 (£26.92 Export Price) plus shipping available from Hannants |

| Review Type: |

FirstLook |

| Advantages: |

The kit features crisp surface details particularly the rib tapes and stitching, a beautiful color photo-etched fret, wheel masks, and a colorful decal sheet with markings for 5 airframes. |

| Disadvantages: |

|

| Conclusion: |

The engineering is simple and straightforward, the details are beautifully rendered and abundant, and the result with the colorful and crisply printed lozenge decals will be spectacular. |

Reviewed by John Miller

Eduard's 1/48 scale Messerschmitt Bf 109 G-14 is available online from Squadron.com

The Fokker D.VII was a German World War I fighter aircraft designed by Reinhold Platz of the Fokker-Flugzeugwerke. Germany produced around 3,300 D.VII aircraft in the second half of 1918. In service with the Luftstreitkräfte, the D.VII quickly proved itself to be a formidable aircraft. The Armistice ending the war specifically required, as the fourth clause of the "Clauses Relating to the Western Front", that Germany was required to surrender all D.VIIs to the Allies. Surviving aircraft saw much service with many countries in the years after World War I.

Design and Production

Fokker's chief designer, Reinhold Platz, had been working on a series of experimental V-series aircraft, starting in 1916, which were notable for the use of cantilever wings. Hugo Junkers and his aviation firm had originated the idea in 1915 with the first practical all-metal aircraft, the Junkers J 1 monoplane, nicknamed Blechesel (Sheet Metal Donkey or Tin Donkey). The wings were thick, with a rounded leading edge. The shape of the airfoil gave greater lift, with its relatively "blunt" leading edge (as seen in cross-section) giving it more docile stalling behavior than the thin wings commonly in use.

In late 1917, Fokker built the experimental V11 biplane, fitted with the standard Mercedes D.IIIa engine. In January 1918, Idflieg held a fighter competition at Adlershof. For the first time, front line pilots participated in the evaluation and selection of new fighters. Fokker submitted the V11 along with several other prototypes. Manfred von Richthofen flew the V11 and found it tricky, unpleasant, and directionally unstable in a dive. Platz lengthened the rear fuselage by one structural bay and added a triangular fin in front of the rudder. Richthofen tested the modified V11 and praised it as the best aircraft of the competition. It offered excellent performance from the outdated Mercedes engine, yet was safe and easy to fly. Richthofen's recommendation virtually decided the competition but he was not alone in recommending it. Fokker immediately received a provisional order for 400 production aircraft, which were named D.VII by Idflieg.

Fokker's factory was not up to the task of meeting all D.VII production orders and Idflieg directed Albatros and AEG to build the D.VII under license, though AEG did not ultimately produce any aircraft. Because the Fokker factory did not use detailed plans as part of its production process, Fokker simply sent a D.VII airframe for Albatros to copy. Albatros paid Fokker a five percent royalty for every D.VII they built under license. Albatros Flugzeugwerke and its subsidiary, Ostdeutsche Albatros Werke (OAW), built the D.VII at factories in Johannisthal [Fokker D.VII (Alb)] and Schneidemühl [Fokker D.VII (OAW)] respectively. Aircraft markings included the type designation and factory suffix, immediately before the individual serial number.

Some parts were not interchangeable between aircraft produced at different factories, even between Albatros and OAW. Each manufacturer tended to differ in both nose paint styles and the patterning and layout of their engine compartment cooling louvers on the sides of the nose. OAW-produced examples were delivered with distinctive mauve and green splotches on the cowling. All D.VIIs were produced with either the five-color Fünffarbiger or less often, the four-color Vierfarbiger lozenge camouflage covering, except for early Fokker-produced D.VIIs, which had a streaked green fuselage. Factory camouflage finishes were often over-painted with colorful paint schemes or insignia for the Jasta or for a pilot.

In September 1918, eight D.VIIs were delivered to Bulgaria and in late in 1918, the Austro-Hungarian company Magyar Általános Gépgyár (MÁG, Hungarian General Machine Company) commenced licensed production of the D.VII with Austro-Daimler engines. Production continued after the end of the war, with as many as 50 aircraft completed.

Powerplants

Many sources erroneously state that the D.VII was equipped with the 120 kW (160 hp) Mercedes D.III engine. The Germans used D.III as a generic term to describe later versions of that engine. The earliest production D.VIIs were equipped with 170–180 hp Mercedes D.IIIa. Production quickly switched to the intended standard engine, the higher-compression 134 kW (180–200 hp) Mercedes D.IIIaü. It appears that some early production D.VIIs delivered with the Mercedes D.IIIa were later re-engined with the D.IIIaü.

By mid-1918, some D.VIIs received the "overcompressed" 138 kW (185 hp) BMW IIIa, the first product of the BMW firm. The BMW IIIa followed the SOHC, straight-six configuration of the Mercedes D.III but incorporated several improvements. Increased displacement, higher compression and an altitude-adjusting carburettor produced a marked increase in speed and climb rate at high altitude. Because the BMW IIIa was overcompressed, using full throttle at altitudes below 2,000 m (6,600 ft) risked premature detonation in the cylinders and damage to the engine. At low altitudes, full throttle could produce up to 179 kW (240 hp) for a short time. Fokker-built aircraft with the new BMW engine were called D.VII(F), the suffix "F" standing for Max Friz, the engine designer.

BMW-engined aircraft entered service with Jasta 11 in late June 1918. Pilots clamored for the D.VII(F), of which about 750 were built. Production of the BMW IIIa was limited and the D.VII continued to be produced with the 134 kW (180 hp) Mercedes D.IIIaü until the end of the war.

D.VIIs flew with different propeller designs from different manufacturers. Despite the variations there is no indication these propellers gave disparate performance. Axial, Wolff, Wotan, and Heine propellers have been noted.

Operational History

The D.VII entered squadron service with Jasta 10 in early May 1918. When the Fokker D.VII appeared on the Western Front in April 1918, Allied pilots at first underestimated the new fighter because of its squarish, ungainly appearance but quickly revised their view. The type quickly proved to have many important advantages over the Albatros and Pfalz scouts. Unlike the Albatros scouts, the D.VII could dive without any fear of structural failure. The D.VII was also noted for its high maneuverability and ability to climb, its remarkably docile stall and reluctance to spin. It could "hang on its prop" without stalling for brief periods of time, spraying enemy aircraft from below with machine gun fire. These handling characteristics contrasted with contemporary scouts such as the Camel and SPAD, which stalled sharply and spun vigorously.

Several aircraft suffered rib failures and fabric shedding on the upper wing. Heat from the engine sometimes ignited phosphorus ammunition until additional cooling louvers were installed on the metal sides of the engine cowling panels and fuel tanks sometimes broke at the seams. Aircraft built by the Fokker factory at Schwerin were noted for their lower standard of workmanship and materials. Despite faults, the D.VII proved to be a remarkably successful design, leading to the familiar aphorism that it could turn a mediocre pilot into a good one and a good pilot into an ace.

Richthofen died days before the D.VII began to reach the Jagdstaffeln and never flew it in combat. Other pilots, including Erich Löwenhardt and Hermann Göring, quickly racked up victories and generally lauded the design. Aircraft availability was limited at first, but by July there were 407 in service. Larger numbers became available by August, when D.VIIs achieved 565 victories. The D.VII eventually equipped 46 Jagdstaffeln and by the wars end in November, 775 D.VII aircraft were in service.

Post-War Service

The Allies confiscated large numbers of D.VII aircraft after the Armistice. The United States Army and Navy evaluated 142 captured examples. Several of these aircraft were re-engined with American-built Liberty L-6 motors, very similar in appearance to the D.VII's original German power plants. France, Great Britain and Canada also received numbers of war prizes.

Other countries used the D.VII operationally. The Polish deployed approximately 50 aircraft during the Polish-Soviet War, using them mainly for ground attack missions. The Hungarian Soviet Republic used a number of D.VIIs, both built by MAG and ex-German aircraft in the Hungarian-Romanian War of 1919.

The Dutch, Swiss, and Belgian air forces also operated the D.VII. The aircraft proved so popular that Fokker completed and sold a large number of D.VII airframes that he had smuggled into the Netherlands after the Armistice. As late as 1929, the Alfred Comte Company manufactured eight new D.VII airframes under license for the Swiss Fliegertruppe.

(Edited from Wikipedia)

Once again, I ambled in to Skyway Models fulfilling my normal Saturday afternoon routine and, once again, I was confronted with a temptation beyond my control: the new Eduard Fokker D.VII. I wasn’t let down. The kit is beautifully rendered and the decals are gorgeous. I’ll be getting another. Well done, Eduard!

In the lidded box typical of this manufacture are two large, bagged sprues each composed of two smaller sprues linked by a round connector. I separated the sprues at the connector to facilitate photography.

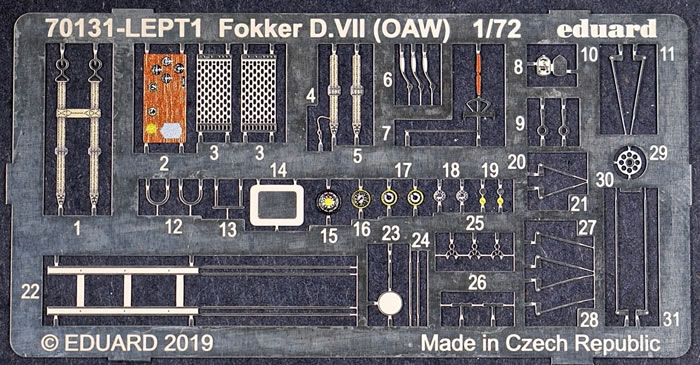

In addition to the book-like instruction manual there are 2 sets of die-cut masks (wheel discs) and a beautiful color PE fret.

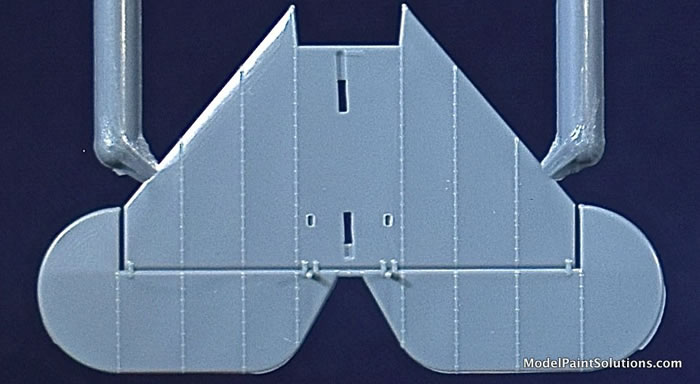

The surface details are beautifully rendered and scale-appropriate. Both the inscribed and outscribed (in relief) details are crisply done. The rib tapes and stitching are particularly well done and will look awesome under paint and washes.

Not all of the parts are used to build the version that is the focus of this boxing: an OAW-produced D.VII with the Mercedes D.IIIa engine.

Layout and engineering are both conventional such that assembly starts with the cockpit. Here the nicely molded instrument panel, floor, seat, and other styrene parts are augmented with multiple pieces of color PE including lap belts.

Next up is the nicely molded multi-part, Mercedes D.IIIa that is captured between the fuselage halves along with the completed cockpit. The machine guns are crisply molded and augmented with photo-etch cooling jackets. Both the vertical stabilizer-rudder and horizontal stabilizer-elevator are single-piece parts making for a quick and easy fuselage assembly. The heavy seam along the centerline of the belly is provided in PE: nice.

The single-piece lower wing fits into a slot in the bottom of the fuselage. Following the addition of the N-struts and cabane struts the single-piece upper wing is added. With the addition of the nicely molded main gear, wheels/tires, and propeller the model is largely complete.

I see no hidden issues laying in wait. This looks like it will be a relatively quick and easy build.

Markings

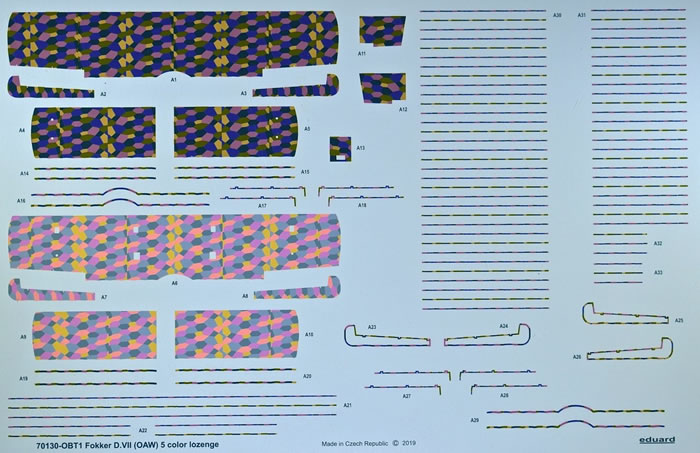

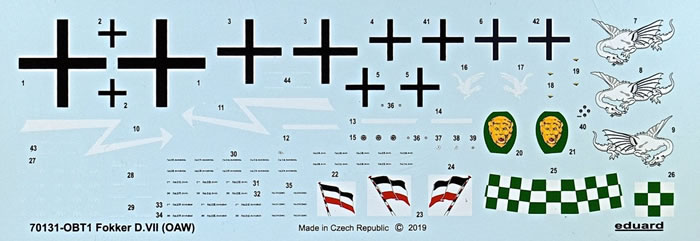

The decals, by Eduard, are crisply printed with appropriate color density and hue.

Two decal sheets are supplied - one with the lozenge and fabric strips, and another with the unique markings.

Markings for four colorful schemes are provided as follows:

-

Ltn. Wilhelm Leusch, CO of Jasta 19, Trier, Germany, October 1918.

-

No. 6441/18, Ltn. Max Näther, Jasta 62, Preutin-Higney, France, October/November 1918.

-

Ltn. Franz Büchner, CO of Jasta 13, Trier, Germany, October 1918.

-

Ltn. August Raben, CO of Jasta 18, Möntingen (Montoy-Flanville now), October 1918.

-

Ltn. Alfred Greven, Jasta 12, Carignan, France, October 1918.

What’s not to like? The engineering is simple and straightforward, the details are beautifully rendered and abundant, and the result with the colorful and crisply printed lozenge decals will be spectacular.

Now go paint something!

For more on this review visit Modelpaintsolutions.com

Kit purchased by reviewer

Review Text and Images Copyright © 2019 by John Miller

Page Created 9 July, 2019

Last updated

26 September, 2019

Back to HyperScale Main Page

Back to Reviews Page |