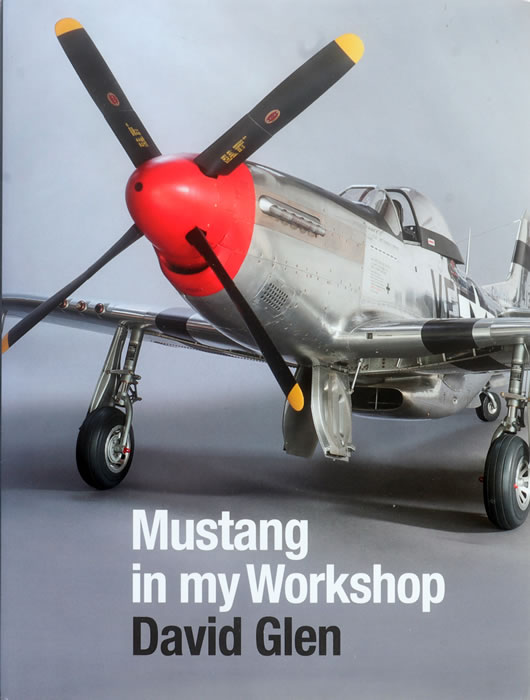

Mustang in my Workshop

by David Glen

Brown and Brown

S u m m a r y : |

Title and ISBN: |

Mustang in my Workshop

by David Glen

Brown and Brown

ISBN: 978-09-563498-9-0 |

Contents & Media: |

Hard cover; 288 large-format pages (325 x 254mm); 2.3kg; 600 colour photographs. |

Price: |

£54.95 plus postage available online from the Author's Warbirds in my Workshop website |

Review Type: |

First Read. |

Advantages: |

High production values incuding glossy heavy weight paper; excellent photography; useful captions and detailed Chapter text; superb model building. |

Disadvantages: |

|

Conclusion: |

David Glen's scratch built 1/5 scale P-51D Mustang is a breathtaking example of inspiring vision and outstanding execution. This book provides a unique insight into the creation of David's masterpiece. Its high production standards and exhaustive illustrated timeline are deserving of this title's unique subject. Whether viewed as a study of a remarkable project or as a jaw-dropping coffee table book, David Glen's "Mustang in my Workshop" will be a conversation starter in your collection. |

Reviewed by Brett Green

David Glen has documented the creation of his magnificent scratch built 1/5 scale P-51D Mustang in detail in his new book, Mustang in my Workshop.

The model was completed in 2014 and is currently on display at the RAF Museum Cosford, where tens of thousands have been able to admire the model close up in its giant custom-made case.

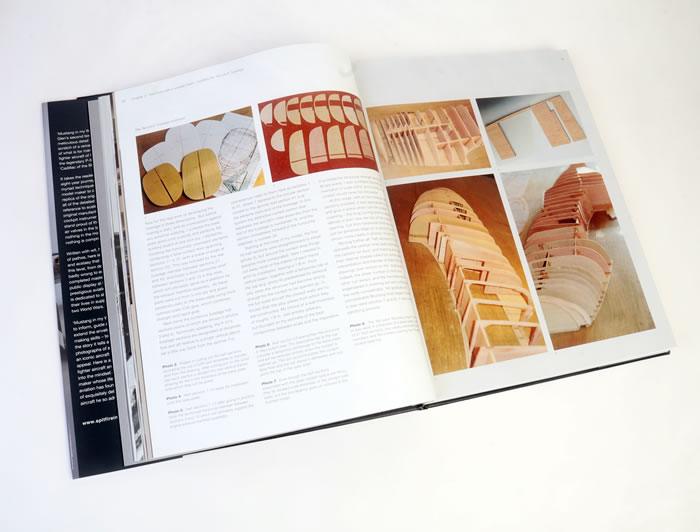

The book comprisess 288 large-format pages (325 x 254mm), weighs 2.3kg and is lavishly illustrated with 600 colour photographs covering every aspect of the project. The photographs are large and accompanied by useful captions in addition to the detailed Chapter text.

This is a weighty tome, quite literally, that delivers an exhaustive illustrated step-by-step chronicle of this scratch built masterpeice.

The specific layout of the book is as follows:

-

Chapter 1: Voyage into the unknown – the vital role of preparation and planning.

-

Chapter 2: Warhorse with a wooden heart – preliminary stages in building the wooden fuselage core and installation of the aluminium main longerons. Ultra-realistic radiator and oil cooler matrices; balsa/ply radiator air scoop and the chin scoop cast in resin.

-

Chapter 3: More woodwork – mainplane and tailplane assemblies take shape; ailerons and flaps; gun ports and wheel bays, and early provision for locking the wings and empennage to the fuselage.

-

Chapter 4: Metal lining the cockpit interior and installing its main structural features: fuselage frames, radio rack and seat support assemblies; building and detailing the fuel tank, cockpit floor assembly and instrument panel and centre console.

-

Chapter 5: Fitting out the cockpit – rudder pedals, switches and switch plates; oxygen regulator, canopy release mechanism, pilot’s main control pedestal, engine control quadrant, joy stick and torque tube, pilot’s seat and armour plate.

-

Chapter 6: Enclosing the cockpit – the windshield and armoured glass; a vac-formed instrument panel shroud and the sliding canopy.

-

Chapter 7: The wheel bays – installing the litho-plate interior skins, internal stringers and rib-lets. A riot of ancillary equipment, hoses, lines and unions – all built directly from the scaled down manufacturer’s drawings.

-

Chapter 8: Fuselage metamorphosis – the transformative magic of litho-plate; what is litho-plate; preparing and using it; the preliminary cladding stages, including nose section and cowling panels; round and flush-headed rivets; coping with compound curvatures.

-

Chapter 9: Metal cladding the mainplanes and empennage – shell chutes, fuel caps and recognition lights; resin wing tips; polished ailerons and ‘quilted’ flaps; elevator, tailplane and fin skins; litho skin blisters and flutes; gun muzzle blisters – a ‘creative’ solution.

-

Chapter 10: The major sub-assemblies united – cladding and fitting the radiator scoop; making and installing the wing root and tailplane fillets; rudder fabric and rib tapes; tail light and other details.

-

Chapter 11: Landing gear – struts, wheels, tyres and doors. Shock struts and fork assemblies; machining the main wheels; the wheel bay doors; the tail wheel assembly and its hidden secrets.

-

Chapter 12: Agony and ecstasy – some ups and downs of model making: exhaust manifold assembly; spinning the spinner; prop blades and cuffs; the vhf radio and battery packs.

-

Chapter 13: Polish and paint – choosing the right materials; acid etch; custom paint masks; data plates and dry transfer rubdowns

-

Afterword: Set course for Cosford.

David Glen's scratch built 1/5 scale P-51D Mustang is a breathtaking example of inspiring vision and outstanding execution.

This book provides a unique insight into the creation of David's masterpiece. Its high production standards and exhaustive illustrated timeline are deserving of this title's unique subject.

Whether viewed as a study of a remarkable project or as a jaw-dropping coffee table book, David Glen's "Mustang in my Workshop" will be a conversation starter in your collection.

Highly Recommended.

Author Biography

David Glen has balanced a career in publishing and journalism with a passion for aircraft and all things aeronautical. He started work in the late 1960s as a trade and technical journalist in Fleet Street, before moving on to contract publishing and PR and ultimately to the frenetic world of creative marketing, where he worked as a company director. In his spare time he indulged his fascination for aviation as a volunteer restorer of veteran warbirds, as a private pilot and – above all – as a model maker.

Following his retirement in 2010, David now devotes his time to building exhibition quality model aircraft and to his writing, which includes numerous articles for the modelling press. He lives with his wife Eva in the tiny South Cambridgeshire village of Whaddon.

Thanks to David Glen for the sample.

Review Copyright © 2022 by Brett Green

This Page Created on 27 May, 2022

Last updated

27 May, 2022

Back to HyperScale Main Page

Back to Reviews Page

|